PURPOSE

The old way never gets old.

In 1921, we decided to make chairs in an uncompromising manner.

That spirit is alive and well today.

We see every chair from start to finish – beginning with raw

lumber, graded, stacked, and dried to absolute perfection.

Then, we build, by hand, for restaurants, pubs, schools,

libraries, resorts and senior living communities; the places

we work hard, have fun, and call home.

At Jasper Chair, we bend the rules, preserve lost arts, and pursue

a level of quality that’s hard to come by – always for our customers,

always with American pride.

Our history is defined by making chairs people love – and at

Jasper Chair, history repeats itself every day.

MANUFACTURING

There are no shortcuts involved in building a chair to last a lifetime. Therefore, we build every chair from scratch, under our roof. From drying raw lumber to final cartoning, we self-perform all stages of building our furniture, so we can fully stand behind what we sell.

We do not import frames; we build our own.

We do not buy dried lumber; we dry our own.

We do not use pre-finished frames or parts;

instead, we fine tune our finish lines to always provide a consistent, environmentally friendly finish.

LUMBER +

GRADING

Each year we purchase over two billion board feet of the finest Northern Grown Red Oak and Hard Maple lumber harvest within the United States. We work with responsible foresters located within the Midwest to ensure quality and availability.

DRYING

This is where we standout from the rest. Our lumber is stored up to a year, dried (yes, by ourselves), graded, and sorted accordingly. Unlike many manufactures that bypass this process for faster methods or purchase dried lumber. Starting with the rawest of materials is how we've always done it and we haven't changed that.

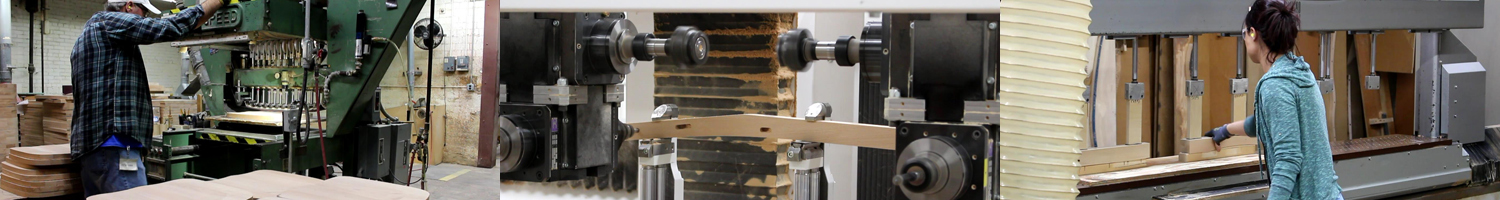

BENDING

BY STEAM

A lost art that adds strength to our chairs. Saturating lumber with steam until the wood fibers are pliable for bending can take two hours for the intensive and costly process. It is a rare process, but the results are exclusive.

MACHINING

Relying on the finest machinery from around the world, we are able to build our product quickly, accurately, and to the highest possible quality.

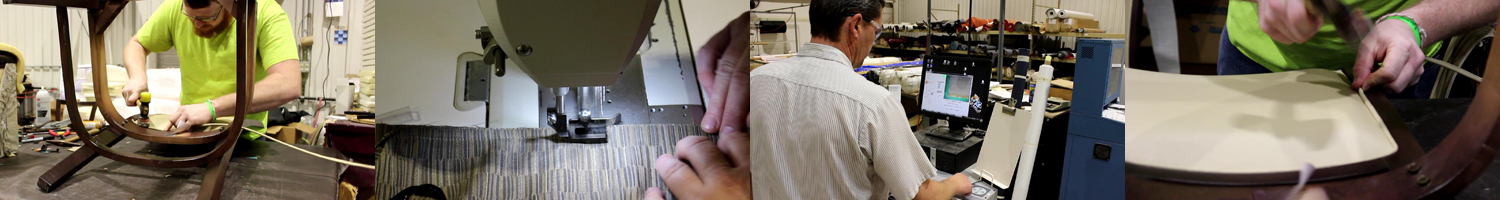

ASSEMBLY

Constant, random quality checks are made through out the assembly process. Frame assembly is controlled to secure proper fit and form. All models are built from individual components, utilize solid wood corner blocks, glue and extra care to ensure structural stability.

SANDING

Before receiving the final sanding every chair is inspected to ensure the proper amount of glue was used and each frame is square and fastened properly. During the sanding process we flush out joints and create smoothness in preparation for finishing.

FINISH

Each chair is put through numerous staining and sanding processes for smoothness. Multiple layers of Catalyzed Varnish are applied to. Chairs pass through several temperature controlled ovens to cure the finish for ultimate durability.

UPHOLSTERY +

FINAL INSPECTION

Material is precisely cut, measured, and upholstered. A final inspection to ensure consistency of the order and all quality standards are met. Then, the product is packaged and prepared for shipping.

STORY

1921

True American Manufacturing.

It was 1921. The clamoring of our country’s rapid economic boom. The lush post-war era. The age of invention. The age of Jazz. The advent of boyhood dreams. The start of Jasper Chair.

With an increase in the manufacturing plants to Jasper, Indiana, we claimed the title of "world's desk & chair city.” These companies, merely babies at the time, surviving the great depression, contribute prosperity and long withstanding futures to the craft, tenacity and heritage of hard working german-dutch population.

Jasper Chair met the demand for high quality office and library seating and soon became known for premium, handcrafted tools of the business trade with the strength to handle the rigors of office and library.

The founder of Jasper Chair, Louis P. Joseph, set out to make chairs, from scratch. While many other companies have gone to sourcing, Jasper Chair maintains the entire process.

1982

We are now in our fourth generation under the Barth family leadership. Around the time of transition from Fred Barth to Jeff Barth, father and son, a shift began. Many local companies continued to focus and compete in the office and education sector, while Jasper Chair continued to increase opportunities within restaurant and hotel. Sales continued to boom.

1990 + 2000

To accommodate equipment and demand, multiple expansions have taken place over the years. Yet, we remain at our original location and have come to occupy a city block.

TODAY + TOMORROW

Our solid, grass-roots approach remains today.

Our authentic custom manufacturing offers solutions for customers at the large, global chains to mom-and-pops, for contract and hospitality markets alike.

Our founding principles ring true today as much as a century ago - skillfully trained craftsmen, using only the finest of raw materials, and investment in technology and equipment to support the latest design trends, with the passion to deliver product made to last a lifetime. We make chairs the only way we know how, the right way.

QUALITY

How we make chairs better.

WOOD

Using only the finest domestic raw materials and dried to absolute perfection

CRAFTSMEN

Employing skillfully trained craftsmen and close monitoring of product processes.

CONSTRUCTION

Integrating consistent construction features in our products so they uniquely last a lifetime.

Interlocking corner blocks & rail joints > Durability and comfort are maximized with Interlocking corner blocks & rail joints to lend superior strength at critical joints and provide optimum support for seat suspension.

Solid wood corner blocks > Frames are reinforced with screws (not just glue) and the use of solid wood corner blocks to provide support at all critical joints.

Flex-o-lator > Select upholstered seats styles utilize a flex-o-lator spring seat for suspensions, extra support and comfort, while reducing the wear on the cushion and fabric for long term performance.

Mortise & Tenon > Joinery is a combination of dowel and mortise and tenon with additional hardened steel fasteners to provide the highest quality frame.

SUSTAINABILITY

Jasper Chair’s environmentally conscious approach is a necessary part of how we do business. We have learned along the way, improved, and are constantly seeking ways to lessen our footprint.

AMERICAN. ALWAYS.

With a single facility, Jasper Chair maintains complete control of our manufacturing processes. We start with raw lumber to a finished product ready to ship. Thus we minimize our reliance of other companies, their ethical standards and cost structure.

TECHNOLOGY + EQUIPMENT

Continual investment in the most modern technology and equipment ensures maximum lumber yield and improved manufacturing efficiency.

EMPLOYEES

Our employees are environmental stewards, delivering protective methods to benefit future generations with our conscientious, sounds manufacturing processes. Jasper Chair promotes company wide recycling and seeks to purchase items with recycled content.

RAW MATERIALS

At Jasper Chair, wood is our primary material. It is the only major building material that grows naturally and is renewable. Wood also provides inherent beauty that minimizes the need to alter its appearance, is a versatile, workable material, and has resounding structural composition. Our accountability to this natural resource has guided our responsible sourcing, handling, and management of this material. We make it our commitment to harvest wood in a way that preserves and replenishes our forests for future generations.

REUSE

With thoughtful consideration, our furniture can always be renewed, reused, and recycled.

We collect all non-usable wood and use it for fuel, creating steam for the manufacturing processes and heat in the winter. This reduces the release of damaging fossil fuels in our facilities and into the air.

REDUCE

Our products are designed to last a lifetime. By making our furniture with close attention to quality construction, it can be an heirloom passed from generation to generation.